New Energies

Heat exchangers for innovative

energy transfer systems

Heat exchangers specifically designed for modern and innovative energy transfer systems.

Solutions made of materials that can withstand high temperatures, high pressure, and corrosive fluids, e.g. welded or diffusion-bonded high-grade stainless steel ones. Typically, those are tailor-made solutions for a particular application.

Overview

The main goal of the New Energy Solutions Division is to support worldwide energy transformation. By providing efficient and reliable solutions, we can assist various heat transfer-related processes in a wide range of green and renewable power industries.

The energy transition is a fact. The dynamically progressing shift from fossil fuels towards renewable and green energy sources would not be possible without effective and reliable heat transfer solutions. At AIC, we develop a broad range of heat transfer solutions designed to work in various green energy applications.

Our devices have been used for many years

in the following applications:

- CHP and mCHP cogeneration system based on fuel cells (i.e. SOFC)

- Concentrated Solar Power Systems

- sCO2 heat pumps and power cycles

- Hydrogen Combustion

- Stirling Engine based systems

- Green fuel processing – hydrogen, green methane

- Syngas processing

The variety and complexity of heat transfer processes for all of the above applications result in the wide range of solutions offered by AIC.

Depending on the individual requirements posed by a given process, our products are based on a number of heat exchange technologies:

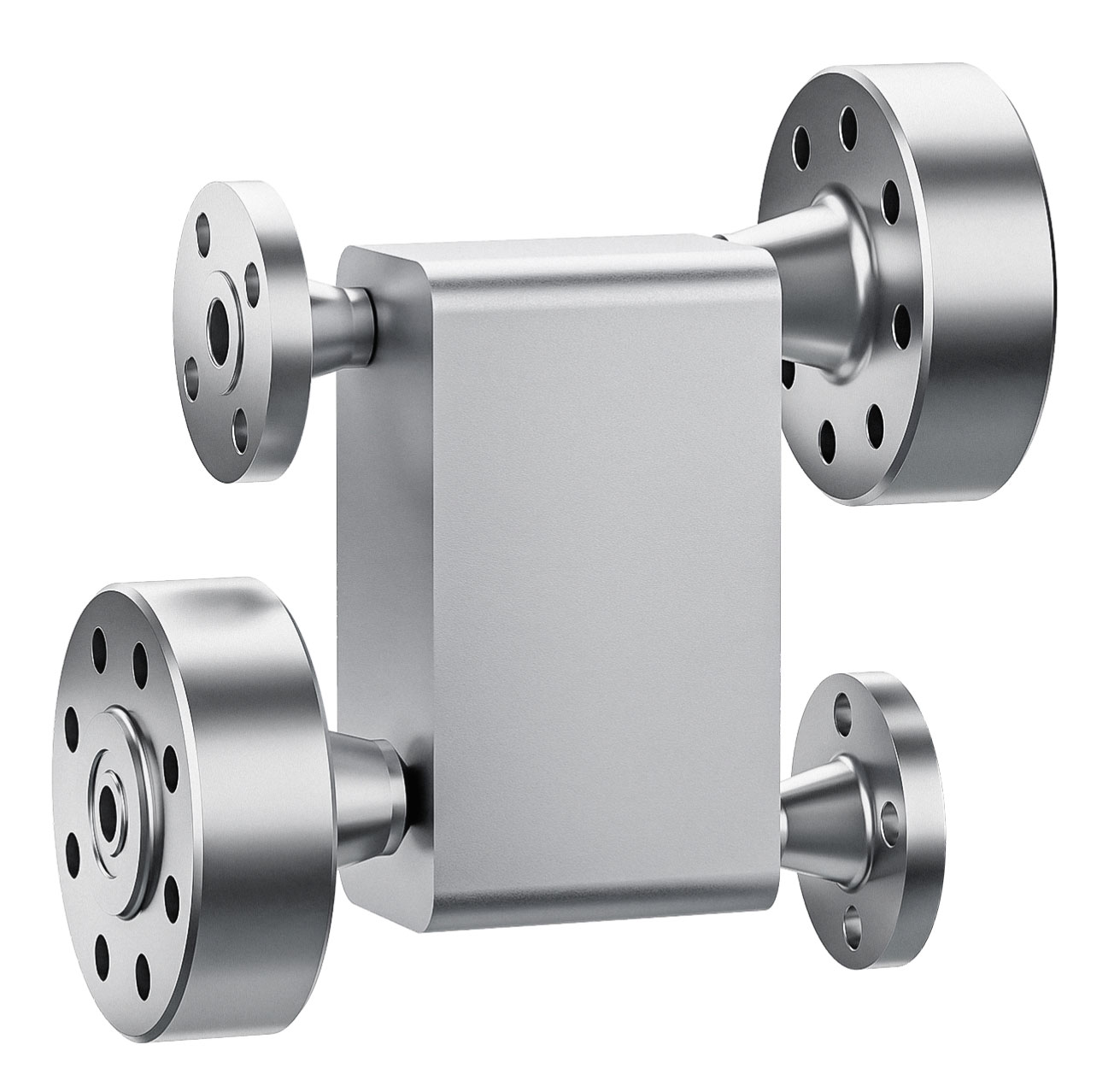

Diffusion-bonded heat exchangers

sCO2 and Hydrogen systems

Brazed compact shell-and-tube heat exchangers

Gas cooling in concentrated solar systems

Welded shell-and-tube heat exchangers

CHP/mCHP systems, hydrogen combustion

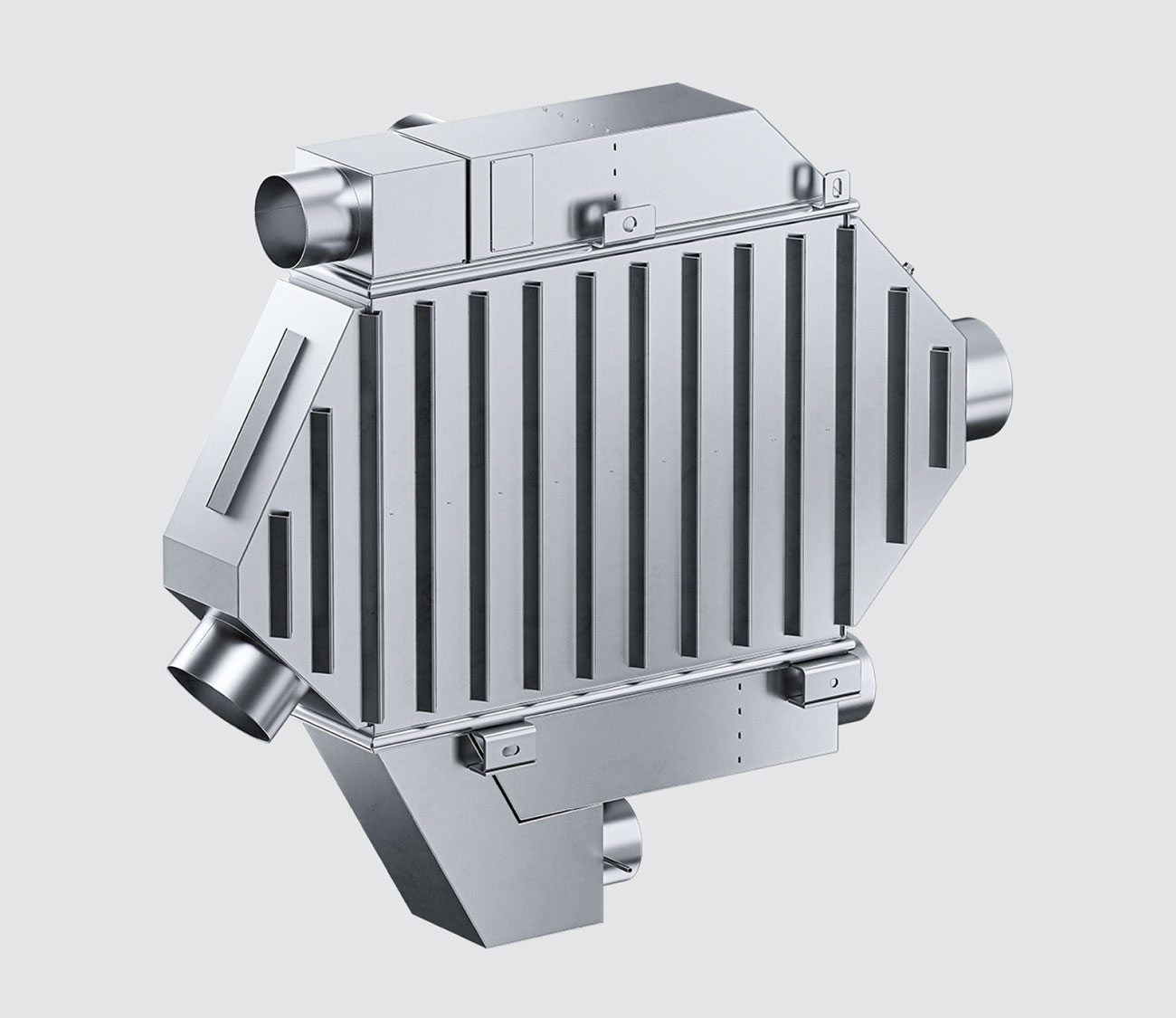

Extended surface-brazed heat exchangers

Fuel cell systems

Auxiliary

components

Auxiliary

components

Apart from heat exchangers, AIC designs and manufactures auxiliary components that are intended to provide efficient and accurate distribution of working fluids (coolants, combustion gases, process gases) in entire systems, such as piping or manifolds.

Looking for a tailor-made heating solution for your industry?

Let us know what you need

All products are made

mostly of stainless steel

and nickel alloys

A certain alloy is selected considering the working environment (working temperatures, medium corrosivity, purity levels) and includes different types of austenitic steel, such as 304L / 316L / 904L (gas cooling system, sCO2 and hydrogen systems), duplex steel, such as 2207 (hydrogen systems, fuel cell systems) and nickel alloys, such as inconel or incoloy (fuel cells and syngas processing).

Other products

Condensing

Economizers

Stainless steel secondary

heat exchangers

Condensing

Boilers

Stainless steel

heat exchangers

Condensing

Water Heaters

Instataneous water heaters

and storage tanks

Industrial

Heat Exchangers

Stainless steel, titanium

and copper heat exchangers

All Heat Exchangers

Custom made heat

transfer solutions