Water Tube

A type of heat exchanger with water flowing inside the tubes, which are enclosed in a combustion chamber.

In a water tube heat exchanger, water circulates in tubes heated externally by hot exhaust gases. This type of device is designed to provide maximum thermal output with the smallest possible footprint.

Overview

A water tube is a type of heat exchanger in which water circulates in tubes heated externally by exhaust gases. Fuel is burned in a combustion chamber, and the hot gases produced in this process pass around the tubes, heating the water inside.

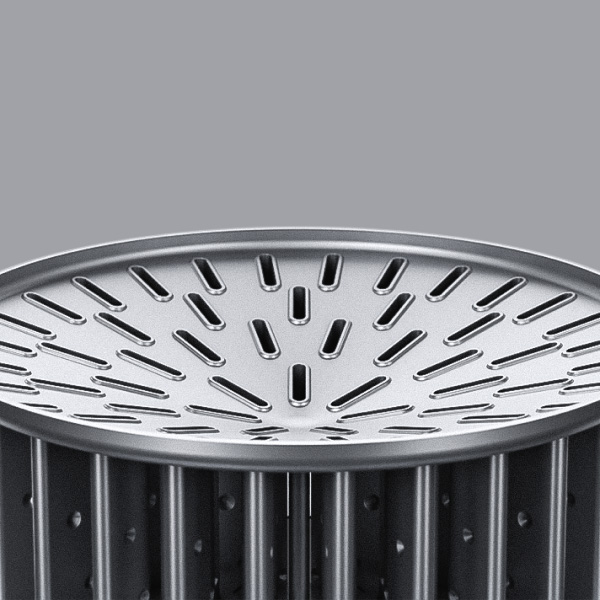

Heat exchange in a water tube device begins in a typically horizontal combustion chamber, where a mixture of air and gas is combusted. The hot gases flow down inside the heat exchanger, enveloping tubes and heating water inside.

Cold water enters the heat exchanger from the opposite side and flows up through the tubes, being heated by the outside gases. The heat is transferred through the walls of the tubes by thermal conduction, which depends on the material properties and the temperature difference between the hot and cold fluids.

Water tube heat exchangers are a popular solution for high-output and residential boilers due to their high power within a small footprint, which makes them easy to transport and install. Such devices are able to operate at high pressures and are therefore suitable for use in a wide range of applications.

Advantages

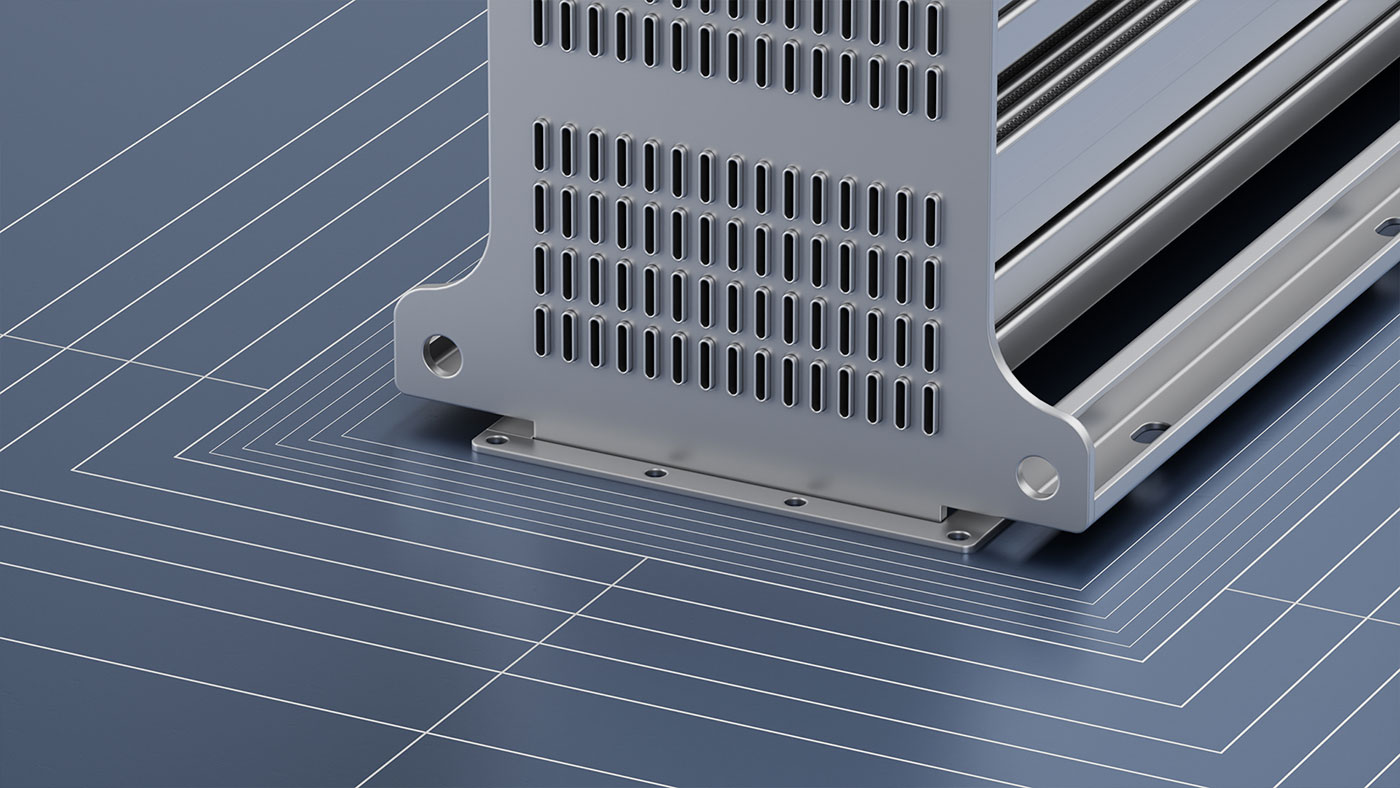

The key advantage of this type of product is its high power output within a small footprint, which allows AIC heat exchangers to fit through a single doorway.

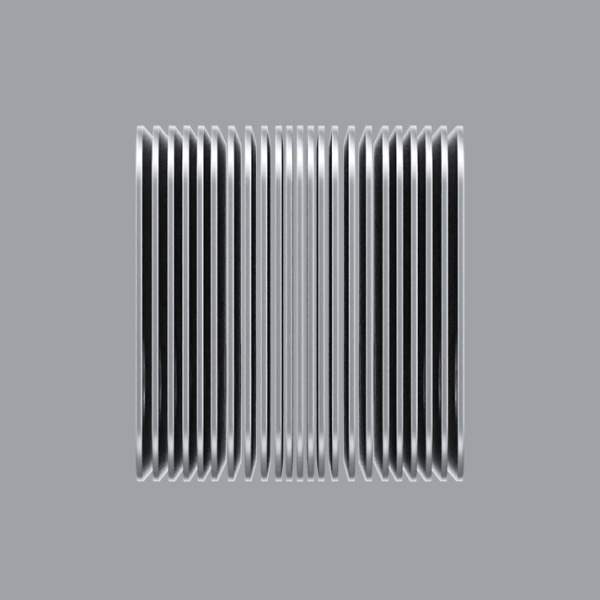

Small footprint

Water tube heat exchangers are relatively compact, which makes them easy to install and transport.

High pressure capability

Water tube heat exchangers are able to operate at high pressures, which makes them suitable for use in a wide range of applications. Additionally the pressure drop at the gas side is low.

Versatility

Water tube boilers can be designed to burn a wide range of fuels, including natural gas and oil.

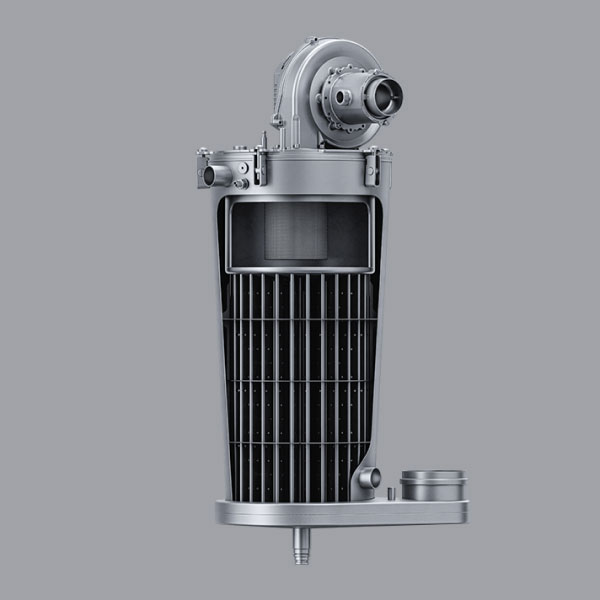

Water Tube designs at AIC

At AIC, we construct high-output condensing heat exchangers with water tube technology. They are engineered to deliver maximum thermal output while having the smallest possible footprint.

AIC has already established a leading position in the market with its fire tube heat exchangers and is now gaining recognition for the water tube product families.

Water tube heat exchangers offer the advantage of having a high power output and a small footprint, so they can fit through a single doorway.

AIC’s high-output water tube boiler is manufactured using a combination of two joining technologies: welding and vacuum brazing. The structure of the heat exchanger consists of two segments: a fully welded upper part - the water tube boiler, and the lower part - vacuum-brazed economizer.