Stainless Steel

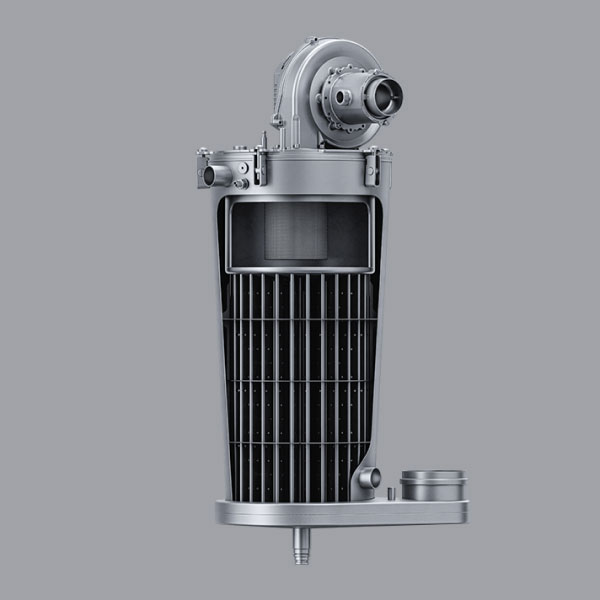

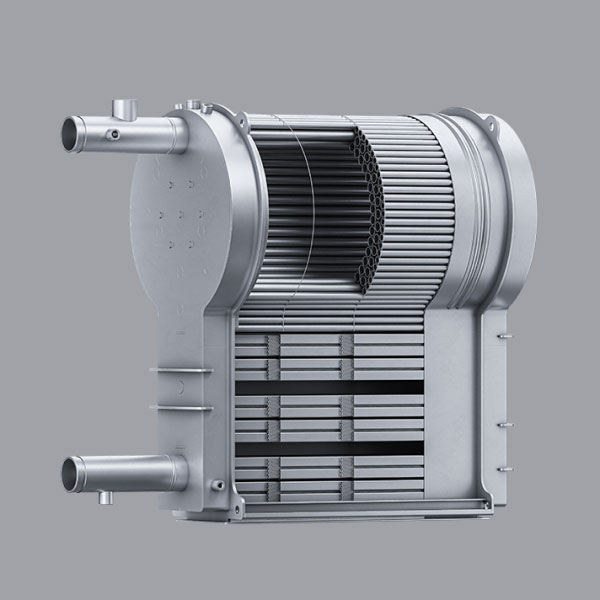

Stainless steel is an essential factor ensuring high resistance to corrosion and durability of our products.

Stainless steel is a perfect material choice for heat exchangers due to its corrosion resistance and strength. It is also a good conductor of heat, which makes it efficient at transferring energy from one medium to another.

Overview

Stainless steel is highly resistant to corrosion due to its chromium content. Chromium forms a thin layer of oxide on the surface, which acts as a barrier to protect the steel from corrosion.

Depending on the grades, stainless steel can maintain exceptional strength at high temperatures or toughness at low, cryogenic temperatures. It is a versatile, durable, and easy-to-maintain material. Its many unique and desirable properties significantly contribute to the widespread use of stainless steel in the production of parts and components across numerous industrial sectors.

There are several types of stainless steel, each with its own unique properties and applications.

The most common types of stainless steel are:

Martensitic stainless steel

This type of steel has good corrosion resistance but low weldability and formability.

Ferritic stainless steel

This type of stainless steel is magnetic and has good corrosion resistance. Ferritic stainless steel shows good weldability.

Austenitic stainless steel

This type of stainless steel is non-magnetic and has good corrosion resistance and high toughness. It is commonly used in the food and beverage industry, as well as in the chemical and petrochemical processing.

Duplex stainless steel

This type of stainless steel combines the properties of both ferritic and austenitic stainless steel, resulting in a material with high strength and good corrosion resistance. It is commonly used in the oil and gas industry and in seawater applications.

Advantages

Stainless steel is a versatile material widely used in many applications due to its strength, durability and corrosion resistance.

- High corrosion resistance

- High strength and durability

- Ability to withstand high temperatures

- Ability to work with a wide range of gases and liquids

- Environmentally friendly and recyclable

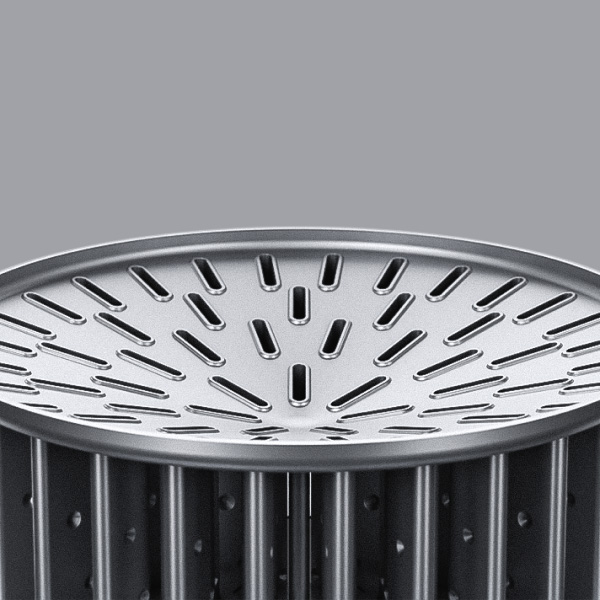

Stainless steel processing

technologies at AIC

With years of manufacturing stainless steel products and components, we’ve mastered steel fabrication skills and developed technologies to process its various types.

With a fully equipped CNC machine park, the whole process of metalworking is carried out in-house, supported by advanced technologies such as mirror laser welding and diffusion bonding.

Our tube manufacturing process starts with R&D department designs and then follows several production steps using different methods of punching, rolling, bending, shaping, and welding.

AIC’s in-house laboratories are able to analyze material structures to apply the most efficient and accurate welding technology and guarantee the high quality of welds.

The digital tracking system allows us to recognize which material has been used in a specific component; all manufacturing processes are recorded and stored in a database.

Although stainless steel is the main material utilized by AIC, we also work with titanium, copper, and other non-carbon steels. All materials used in our factory are certified and supplied by European mills.